MFC Motor

Overview and Key Concepts

The Mass Flow Conveyor (MFC) Motor is used to control the speeds of multiple MFC sections. When the motor's speed is changed, all connected sections will change to the motor's speed. If the motor is stopped either through code, a Time Table or MTBF/MTTR object, all of the motor's connected sections will also stop.

States

The MFC motor doesn't implement any states.

Events

The MFC motor has the following events:

- On Speed Change - Fires when the motors speed is changed. This

event has the following parameters:

Parameter Type Description Old Speed double The motor's speed prior to the speed change. New Speed double The motor's new speed. - On Message - See Object event.

- On Stop - See Object event.

- On Resume - See Object event.

Properties

The MFC motor object has three tabs with various properties. The last three tabs are the standard tabs that are common to all objects. For more information about the properties on those tabs, see:

Only the Motor tab is unique to the MFC motor object. The properties on this tab will be explained in more detail in the following sections.

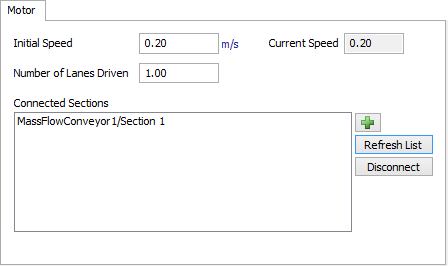

Initial Speed

This number is the speed of the motor when the model is reset.

Current Speed

This is the current speed of the motor.

Number of Lanes Driven

If a section only has one motor connected to it, the Number of Lanes Driven is ignored. When two motors are connected to a section, this number gives a weight to each motor. If Motor1's Number of Lanes Driven is equal to 1 and Motor2's Number of Lanes Driven is equal to 6 then the speed of the section would be equal to:

sectionSpeed = (motor1Speed * motor1Lanes + motor2Speed * motor2Lanes) / (motor1Lanes + motor2Lanes)Connected Sections

This list displays the motor's connected sections. It has the following options:

- Sections List - Displays the currently connected sections. Each section can have up to two connected motors.

- Displays a list of Mass Flow Conveyors

and their sections that can be connected to this motor. You can also connect the motor to a section in

the 3D view by holding the A key and click-dragging from the motor to a section.

- Displays a list of Mass Flow Conveyors

and their sections that can be connected to this motor. You can also connect the motor to a section in

the 3D view by holding the A key and click-dragging from the motor to a section.- Refresh List - Refreshes the list of connected sections.

- Disconnect - Disconnects the selected section from the motor. Sections can also be removed in the 3D view by holding the Q key and click-dragging from the motor to a section.