Model Validation

One of the key principles of simulation modeling is that you need to put good data into

your model in order to get good data out of your model. (See

Data Gathering

Strategies for more information.) That's why you should always test and validate the

first draft of your simulation model to ensure it's an accurate representation of your

business system.

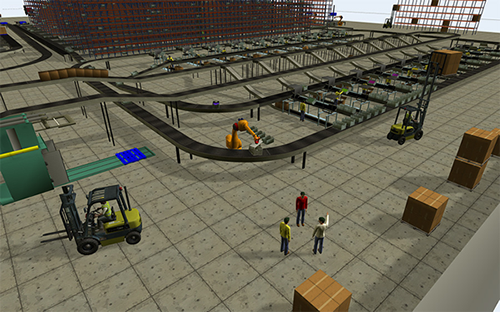

Fortunately, 3D models are much easier to validate for various reasons. One reason is

that 3D models are more grounded by the physical realities of your facility layout. One of

the drawbacks of building purely theoretical models is that you might make a few flawed

assumptions because you might have overlooked certain physical realities in the model.

For example, a 3D model can more accurately represent the amount of time it takes an an

object to travel from one location to another. The 3D model can take into consideration

simple things like distance and speed, but also the route the object takes, interaction with

other objects in its path, and more. These spatial interactions would be very difficult to

simulate in a purely theoretical model.

Another reason is that when you watch your 3D model in action, certain things that don't

seem realistic will become more apparent. Mistakes based on flawed assumptions will seem to

jump out at you during a simulation run because they won't look or feel the same as the

business system you are simulating. Because 3D models are more intuitive and realistic, they

reduce the amount of errors that could be made in the process of building a simulation

model.

Ease of Use

In some cases, it is easier to model certain behaviors or conditions in a purely

theoretical Process Flow model. For example, it is often easier to create custom logic in

Process Flow. However, there are still a number of situations in which it is easier to use

3D objects. Many of FlexSim's library objects use built-in logic that is common in a variety

of business systems, such as production lines. Building a 3D model might actually be easier,

depending on the kind of simulation model you are creating.

Telling a Story

Because they are more visual, 3D models can sometimes be more effective than graphs,

statistics, or PowerPoint presentations when you need to communicate with stakeholders or

new employees. 3D models are especially effective at communicating with key decision-makers

who do not necessarily have a technical or engineering background. For example, it can be

effective to show a stakeholder a series of graphs and charts to demonstrate that your

system is experiencing a bottleneck. But it's usually more powerful for them to look at a 3D

model and see a large stack of boxes piled up inside a queue.

To give another real-world example, FlexSim's 3D objects once helped a client secure a

lucrative international business deal. Because there were significant language and culture

barriers between the client and its international customer, the business deal was in danger

of getting rejected. However, the client built a 3D model of the proposed business system in

FlexSim. Then, they sent a video of the simulation model to the key business decision

makers. Once the stakeholders could see the 3D model, they were able to catch the vision of

the proposal and the business deal was approved.

By learning how to use 3D objects in the rest of this chapter, you'll hopefully be able

to build more accurate simulation models that also communicate your ideas as effectively as

possible.