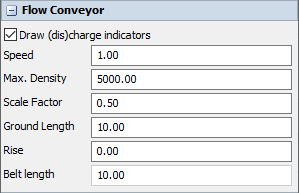

The Flow Conveyor Panel

The Flow Conveyor panel is shown for (non-accumulating) flow conveyors and (accumulating) mass flow conveyors.

The following properties are on the Flow Conveyor panel:

Draw (dis)charge indicators (flow conveyor only)

When this option is enabled, small conical arrows will be drawn over the input points of the conveyor and below the output point of the conveyor. The color of the input arrows indicates the product entering at that point. If more than one product is entering at the same point, the input indicator will have the color of the last entering product (the port with the highest port number) as this will be the product at the top of the stack. In addition, if the flow rate of a port is zero, a small square will be drawn under the conical arrow, "blocking" the input from entering. In the example below, there are two inputs: green product is entering at the start of the conveyor. There is another input connected at 1 m from the start of the conveyor which will provide blue product, but it is currently blocked (in this case, output of the source was closed). Similarly the output indicator drawn below the output point at the end of the conveyor indicates, by its color, the product that is flowing out of the conveyor; a square "blocking" it from below means that no output is currently taking place.

Conveyor speed

The speed of the conveyor determines how fast products will reach the end, but also how tall they will be on the conveyor. The actual size of the conveyor is used, so an inflow of 100 per time unit on a conveyor of 20 length units wide will be 5 length units tall.

Maximum density (mass flow conveyor only)

For the mass flow conveyor, this setting determines how tall product may "stack up" against the end of the conveyor before it starts "crawling back" towards the start. By taking into account the width of the conveyor, the maximum density can be converted into a maximum product height and vice versa. The image below shows how having a relatively small maximum density will make the conveyor fill up relatively quickly.

Scale factor

Scales the height of the conveyor contents (not the actual conveyor object). In the example given under "conveyor speed": if you would set the scale factor to 0.2, the product on the conveyor would only be drawn 5 × 0.2 = 1 length unit tall. This may be useful if you have flows that would otherwise be so small that you cannot see any differences in height or which products are stacked; or when the speed is so low and volume so high that there would be an unrealistically tall "wall" of product running over the conveyor.

Ground length

This is the length of the conveyor as measured along the ground. Currently FloWorks conveyors do not support multiple sections.

Conveyor rise

This is how many length units the conveyor rises along its complete length; in other words, what the height difference is between the start and end of the conveyor.

Belt length

This is an automatically calculated field, that shows you what the actual conveyor belt length would be based on the ground length and conveyor rise. According to the Pythagorean theorem, the belt length is given by B2 = L2 + h2, where B is the belt length, L is the ground length and h is the rise.