Motor

Overview and Key Concepts

Motors can be used to control whether the conveyor systems are on or off at a given time. The motor can also be used to sync dog gaps on a power and free chain loop when simulating a power and free conveyor system.

Events

For information on events, see the Event Listening page.

The motor has the following events:

Event Name

Explain the event. When does the event occur?

It has the following parameters:

| Event Parameter | Type | Explanation |

|---|---|---|

| Parameter Name | Type | Description |

Return value (if applicable)

States

The motor does not implement any states.

Statistics

The motor does not track any statistics.

Properties

Motor properties can be edited in Quick Properties or the Motor property window. The following sections explain the available properties in each tool.

Quick Properties

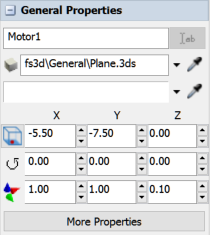

The following image shows the motor properties that are available in Quick Properties:

It has the following properties:

Name

You can type a custom name here if needed.

Color

Use the color selector to change the color of the merge controller.

Position, Rotation, and Size

Changes the position of the merge controller in the 3D model:

| Icon | Description |

|---|---|

|

Change the position of the object. |

|

Change the rotation of the object. |

|

Change the size of the object. |

Property Window

The motor object properties window has three tabs with various properties. The last two tabs are the standard tabs that are common to all conveyor objects. For more information about the properties on those tabs, see:

Only the Motor tab is unique to the motor. The properties on this tab will be explained in more detail in the next section.

The Motor Tab

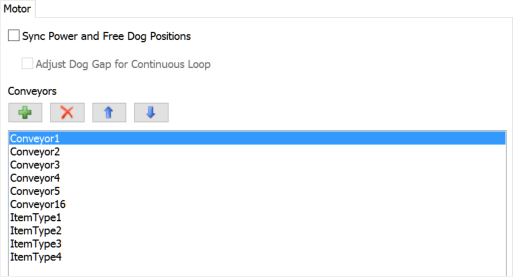

The Motor tab has the following properties:

Sync Power and Free Dog Positions

This checkbox is for use with power and free conveyor systems. If this box is checked, the motor will ensure that the initial dog positions will be aligned on all of the conveyors connected to it. For example, if the motor's first connected conveyor is 10.2 meters long, and the dog gap is 1.0 meters, then it will set the dog position to start at 0.0 on the first conveyor and at 0.8 on the second connected conveyor (the remaining distance to the next dog after the end of the first conveyor).

If this box is unchecked, or if Power and Free conveyors do not have an associated motor, the dog positions will be defined automatically when the first item enters the conveyor.

Adjust Dog Gap for Continuous Loop

When this box is checked, the motor will assume that the conveyors connected to it represent a looping Power and Free chain. The motor will calculate the total length of the loop based on the combined lengths of the connected Power and Free conveyors and will adjust the dog gap of each conveyor so that the total length of the loop divides evenly by the dog gap. For example, if the total length of a motor's conveyors adds up to 100.2 meters, and the dog gap is 1.0 meters, the motor will adjust the dog gap of each conveyor to be 1.002 meters (100.2 / 100), so that the full loop makes up exactly 100 dogs. The algorithm rounds to the nearest number of dogs. This checkbox is only available if the Sync Power and Free Dog Positions checkbox is also checked.

Conveyors

You can use this to add, remove, or reorder the conveyors that are connected to the motor.