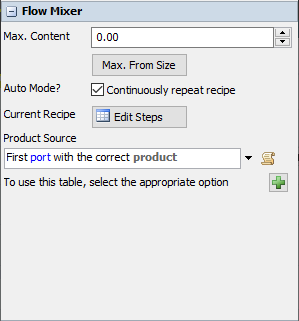

The Flow Mixer Panel

The flow mixer panel is shown for flow mixers.

The following properties are on the flow mixer panel:

Max. Content

The maximum content that the flow tank can contain. The mixer will never exceed this value and upon reaching it the "On Full" event will occur. Please be careful to set the maximum content of the mixer to a value that is large enough to be able to contain all ingredients for the largest batch of product you (may) wish to create on the mixer.

Calculate Max. From Size

Calculate and set the Max. Content field to the volume of the object as it is in the model.

For regular flow tanks, this calculates πhr2, where h is the height of the tank and r its radius. The radius is determined by the x-size of the object, the y-size is ignored. If the level indicator is set to Rectangular, the maximum content is calculated according to xyz where x, y, z are the dimensions of the tank.

The maximum content is converted to model fluid units - for example if your length units are meters and the fluid units are liters, the maximum content will be set to the value described above times 1000, since 1 m3 = 1000 L.

Auto Mode? (Continuously repeat recipe)

When this box is checked (the default when you drag a new mixer into the model), the flow mixer operates in automatic mode. This means that it will start collecting ingredients for the first step of the recipe as soon as the model is started. As soon as a batch has been completely released and the mixer is empty again, it will also immediately start working on the next batch.

Sometimes you need more fine-grained control over when the mixer starts working on a batch. For example, you may want to collect enough material in the supply tanks before you start

mixing the next batch, or you may have a production schedule to run and want to dynamically change the recipe between different batches. If this is the case, you can disable the

"Continuously repeat recipe". The mixer will now remain idle until you start a recipe using the "Start mixer Recipe" trigger option or the

Flowmixer.startRecipe() method.

Current recipe

The Current Recipe popup shows the recipe that the mixer is currently executing. By default, this will be the recipe that you entered; however if you set the mixer to manual mode and call Flowmixer.loadRecipe

(or select the Load mixer Recipe option from a trigger picklist) this table will be overwritten with the loaded recipe.

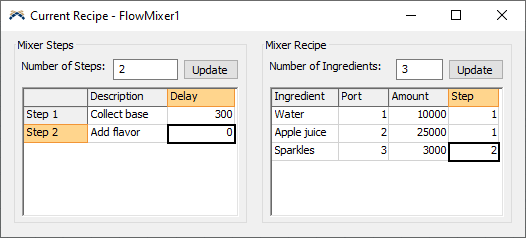

The popup has the following two panels.

Mixer Steps

Defines the number of steps and the delay after each step. To change the number of steps, fill in the required number in the "Number of Steps" field and click "Update". The description in each step is just for your convenience: it is ignored by the mixer logic. You will reference the step by rank in the Recipe table.

Mixer Recipe

In this table you define exactly which ingredients should be collected, in what amount, from which source and in which step. As described above, all ingredients for the same step will be collected simultaneously.

Product sources

The product sources trigger specifies from which input port the mixer should get its products when loading a global product recipe. For more information about defining global recipes, see the Product page. In summary, in the global product recipe you specify the steps and ingredients just like you would in the Current Recipe Tab of the mixer, except that in the recipe steps you do not specify specific input ports but product types. The reason is that you can load the same recipe into different mixers, which may have different configurations for their input ports. For example, one mixer may get product A from input port 1 while another mixer gets the product from input port 3. The purpose of the Product Sources table is to convert these global product ingredients to specific input ports numbers when loading the recipe into the Current Recipe table of the mixer.

The Product Source trigger has the following parameters:

| Event Parameter | Explanation |

|---|---|

| product | The name or the number of the product. In general, this trigger will be called when you are using named products so this will contain the name of the product. If you need the product ID, call the GetFlowProductId function. |

| step | The step number. You may want to get the same product from different input ports, depending on which step of the recipe the mixer is collecting. |

The product sources trigger should return the number of an input port. By default, the following two options are available in the dropdown:

- First port with the correct product.

The mixer will automatically determine a port to get the product from. It will go through all its input ports, starting at 1, and pick the first port for which the input object has the sought product ID.

This picklist option assumes that all input objects are

FlowObjects. - Use product sources table. This pick option references the product sources table below the product sources trigger. Using the green "Plus" button in the top right corner you can add new rows to this table. On each row, specify one possible product that the mixer can collect, and which input port number to collect it from.