Emulation

Overview and Key Concepts

The Emulation tool creates a link between FlexSim and external PLCs or

clients/servers that communicate with PLCs. This tool can create

multiple connections and define variables for each of those connections.

This tool supports multiple protocols, including Modbus, OPC DA, OPC UA,

MQTT and manufacturer specific like Allen-Bradley, Siemens, Beckhoff and

Mitsubishi.

The Emulation tool is accessed from the Toolbox.

Licensing

Emulation License allow FlexSim user access to all Emulation connections. Modbus RTU/TCP and OPC DA connections are freely available to all FlexSim users.

In the same FlexSim model, user can create an unlimited number of connections mixing different protocols. Limitations are only related to model complexity, computer and communication network performance.

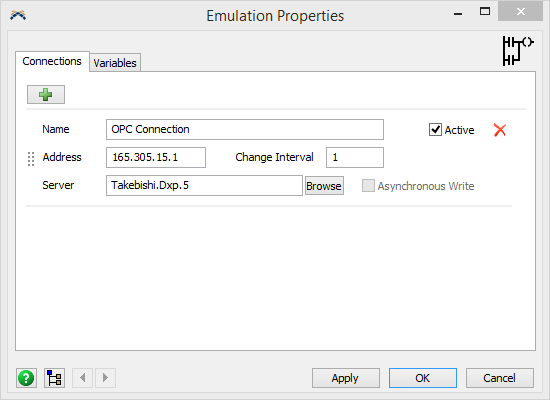

The Connections Tab

The Connections tab has the following properties:

- Adds a new

connection.

- Adds a new

connection.

- Removes the

connection.

- Removes the

connection.

The following connection types are available:

| Connection | Description |

|---|---|

| Modbus RTU | A connection to a modbus slave or master using a serial (RS-232 or RS-485) port. |

| Modbus TCP/IPv4 | A connection to a modbus client or server over ethernet using TCP/IPv4. |

| Modbus TCP/IPv6 | A connection to a modbus client or server over ethernet using TCP/IPv6. |

| OPC DA | A connection to a local or remote OPC server using the Data Access (DA) protocol. |

| OPC UA | A connection to a local or remote OPC server using the UA (unified architecture) protocol. |

| Allen-Bradley | A connection to an Allen-Bradley PLC that support the CIP/EIP protocol. |

| Siemens S7 | A connection to a Siemens SIMATIC S7 PLC, using Snap7 libraries. |

| Siemens PLCSIM Advanced | A connection to a local or remote Siemens SIMATIC S7-PLCSIM Advanced V3.0 instance. |

| Beckhoff | A connection to PLCs or PLC simulators of the Beckhoff family. |

| Mitsubishi | A connection to Mitsubishi MELSEC iQ-R or Q/L series PLCs using the MC (MELSEC Communication) protocol. |

| MQTT | A connection to a MQTT broker. MQTT connection can publish and subscribe topics. |

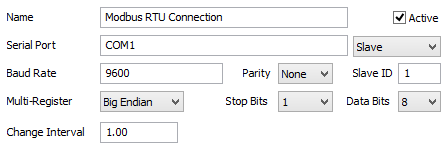

Modbus RTU

Modbus RTU connections can be real, meaning FlexSim will communicate through a physical serial port on the computer, or they can be virtual, meaning a software program emulates a serial port.

- Name - The name of the connection. Used for identifying the connection in FlexSim.

- Active - If checked, a connection will be created to connect FlexSim to the Modbus Slave or Master through a serial port (virtual or real). This occurs on model reset for slave connections and when the model starts running for master connections.

- Serial Port - The serial port to create the connection on.

- Slave / Master - Specify if the connection is a Slave or Master. Slave connections allow other modbus devices/applications to connect to FlexSim.

- Baud Rate - The baud rate of the connection. The baud rate defines the number of signaling events across the transmission per time.

- Parity - Specify if the connection has a parity. This is a method for detecting errors in transmissions.

- Slave ID - Define the Slave ID of the connection.

- Multi-Register - Specify the endianness of the connection or the order of byte transmission.

- Stop Bits - Specify the number of stop bits or bits at the end of each character in the transmission.

- Data Bits - Specify the number of data bits each character in the transmission can be.

- Change Interval - The time interval, in model time units, for FlexSim to poll the slave for changes. This is only available for master connections.

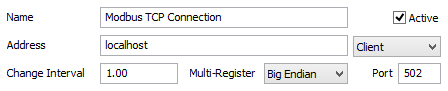

Modbus TCP/IPv4 and IPv6

The properties for IPv4 and IPv6 are identical. The only change is in which protocol is used in setting up the connection. Modbus TCP connections can be real, meaning FlexSim will communicate through a physical ethernet port on the computer, or they can be virtual, meaning a software program emulates a TCP connection.

- Name - The name of the connection. Used for identifying the connection in FlexSim.

- Active - If checked, a connection will be created to connect FlexSim to the Modbus Client or Server through an ethernet port. This occurs on model reset for server connections and when the model starts running for client connections.

- Address - The ip address of the connection. Use localhost to create a connection with a virtual client or server or specify the ip address in the form of 190.123.10.1.

- Type - Specify if the connection is a Client or Server. Server connections allow other modbus devices/applications to connect to FlexSim.

- Change Interval - The time interval, in model time units, for FlexSim to poll the server for changes. This is not used for Server connections.

- Multi-Register - Specify the endianness of the connection or the order of byte transmission.

- Port - The port of the connection.

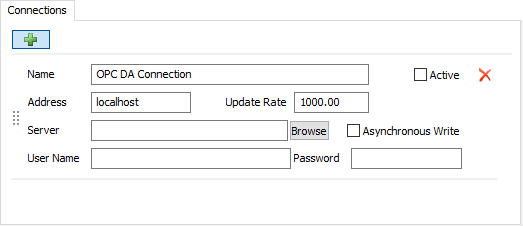

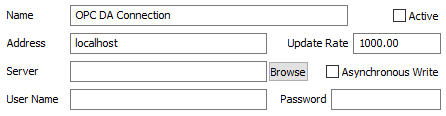

OPC DA

OPC DA connections can be real, meaning FlexSim will communicate through a physical ethernet port on the computer, or they can be virtual, meaning a software program emulates a TCP connection.

- Name - The name of the connection. Used for identifying the connection in FlexSim.

- Active - If checked, a connection will be created to connect FlexSim to an OPC DA server. This occurs when the model starts running.

- Address - The IP address of the

server to connect to.

Use 'localhost' to create a connection with a server on this computer or specify the IP address.

A server can host more than a OPC DA server that can be listed using the 'Browse' button. - Update Rate - The time interval, in model time units, for FlexSim to poll the server for changes.

- Server - The server to connect to. This is a Prod ID of a

- Browse - Click the browse button to display a list of possible servers to connect to at the defined address.

- Asynchronous Write - If checked, writing data to the server will cause FlexSim to wait until the write operation is complete before continuing execution.

- User Name - Used for server authentication if a user name is required to connect to the OPC server.

- Password - Used for server authentication if a password is required to connect to the OPC server.

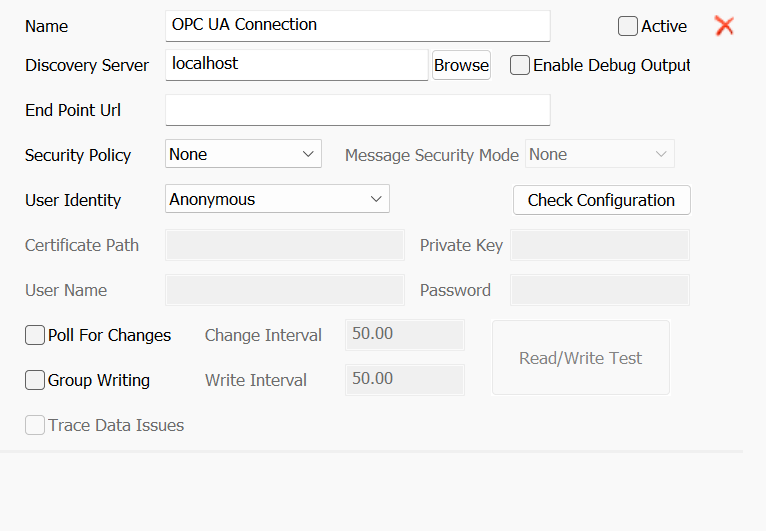

OPC UA

OPC UA connections can be real, meaning FlexSim will communicate through a physical ethernet port on the computer, or they can be virtual, meaning a software program emulates a TCP connection.

- Name - The name of the connection. Used for identifying the connection in FlexSim.

- Active - If checked, a connection will be created to connect FlexSim to an OPC server. This occurs when the model starts running.

- Discovery Server - The IP address

of the discovery server.

Use localhost to discover servers on this computer, or specify the IP address.

Discovery Server use TCP port 4840, by default.

To use another port append this number to the IP address, separated by a ":".

Then you can press the Browse button to browse for specific end point URLs to connect to. - Enable Debug Output - When checked, FlexSim will output information to the system console as it communicates with the server.

- End Point URL - The specific URL defining the server and protocol to connect to. You can auto-fill this field using the Browse button.

- Security Policy - Defines the set

of security algorithms and key length to use when communicating with

the server.

- None - No security is applied.

- Basic128Rsa15 - Uses an Aes 128 symmetric encryption algorithm, a SHA1 key hash, and RSA-PKCS15 asymmetric signature algorithm. Note that this policy is no longer considered secure, since SHA-1 was broken in 2017.

- Basic256 - Uses an Aes 256 symmetric encryption algorithm, a SHA1 key hash, and RSA-PKCS15 asymmetric signature algorithm. Note that this policy is no longer considered secure, since SHA-1 was broken in 2017.

- Basic256Sha256 - Uses an Aes 256 symmetric encryption algorithm, a SHA2-256 key hash, and RSA-PKCS15 asymmetric signature algorithm.

- Message Security Mode - Defines

the message security mode.

- None - No security is applied.

- Sign - Messages are signed but not encrypted.

- Sign&Encrypt - Messages are signed and encrypted.

- User Identity - Define how, or if,

the client user will be identified. The following options are

available:

- Anonymous - No authentication will be used.

- User Name - Specify the user name and password to authenticate with the server.

- Certificate - Use this option if you have a server generated certificate that has been downloaded to the computer running FlexSim.

- Check Configuration - Press this button to check that the entered settings correctly connect to the target UA server.

- Cerificate Path - The file path to the certificate.

- Private Key - The private key associated with the specified certificate.

- User Name - The user name to authenticate with the server.

- Password - The password of the certificate or the user.

- Poll For Changes - When checked, all Control Variable's values of the connection will be sampled together at the specified interval. This option will disable the standard OPC UA subscription mechanism to read data values.

- Change Interval - Define the sampling interval when using 'Poll For Changes' option.

- Group Writing - When checked, all Sensor Variable's values of the connection will be written together at the specified interval. Using this option Sensor Variable values will no send immediately to the OPC UA sensor when changing in FlexSim, but together at next 'Write Interval'.

- Write Interval - Define the writing interval when using 'Group Writing' option.

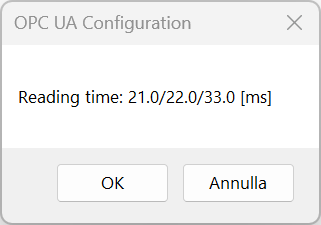

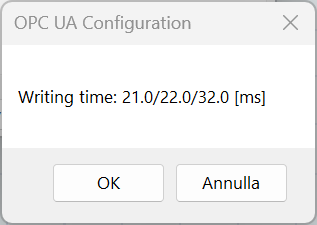

- Read/Write Test - Allow to perform

read/write test to estimate performances.

It is available only when "Poll For Changes" or "Group Writing" are selected.

When "Poll For Changes" is checked press the button to perform a read test.

The result will display a GUI with 3 values: minimum / avg / maximum:

Otherwise if "Group Writing" is selected press the button to perform a write test.

The result will display a GUI with 3 values: minimum / avg / maximum:

- Trace Data Issues - When checked further information when communicate with the OPC UA server will be displayed in the output/system console.

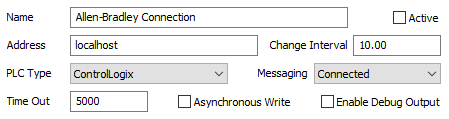

Allen-Bradley

Allen-Bradley connections can be real, meaning FlexSim will communicate through a physical ethernet port on the computer, or they can be virtual, meaning a software program emulates a TCP connection.

- Name - The name of the connection. Used for identifying the connection in FlexSim.

- Active - If checked, a connection will be created to connect FlexSim to an Allen-Bradley PLC. This occurs when the model starts running.

- Address - The ip address of the connection. Use localhost to create a connection with an emulated PLC on this computer or specify the ip address in the form of 190.123.10.1.

- Change Interval - The time interval, in model time units, for FlexSim to poll the PLC for changes.

- PLC Type - The type, or family, of PLC this connection will be connected to. The correct PLC type needs to be specified in order for the connection to work properly.

- Messaging - This option is only available for certain PLC Types. When available, there are two options, Connected and Unconnected. Connected messaging causes FlexSim and the PLC to create an explicit connection where multiple messages can be communicated over a period of time. Unconnected messages are sent from FlexSim to the PLC as single requests.

- Time Out - The time interval, in milliseconds, that FlexSim will use when reading or writing values to the PLC. A time out failure will

- Asynchronous Write - If checked, writing data to the PLC will cause FlexSim to wait until the write operation is complete before continuing execution.

- Enable Debug Output - When checked, FlexSim will output information to the system console as it communicates with the PLC.

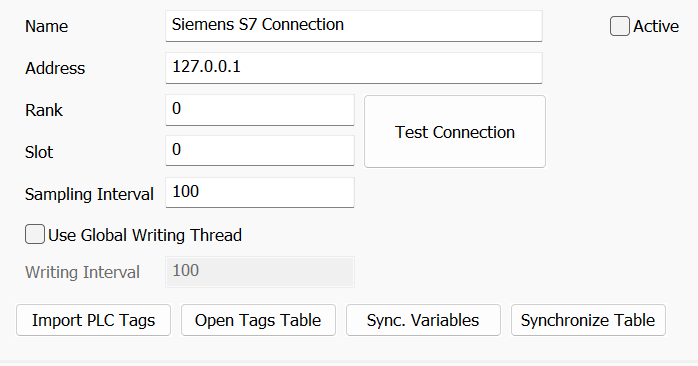

Siemens S7

S7 connection sets FlexSim communicate with Siemens SIMATIC-S7 PLCs. It's based on popular Snap7 Libraries and it's compatible with CPU families 300, 400, WinAC, 1200, 1500, CP343 and CP443

- Name - The name of the connection. Used for identifying the connection in FlexSim.

- Active - If checked, a connection will be created to connect FlexSim to an S7 PLC. This occurs when the model starts running.

- Address - The ip address of the PLC to connect to.

- Rank / Slot - Rank and slot of the

PLC: this fields must be filled according with the required PLC.

PLC Family Rank Slot Notes S7 300 CPU 0 2 Always S7 400 CPU Not Fixed Follow the hardware configuration WinAC CPU Not Fixed. Follow the hardware configuration S7 1200 CPU 0 0 Slot can be 0 or 1 S7 1500 CPU 0 0 Slot can be 0 or 1 CP 343 0 0 Or Follow the hardware configuration CP 443 Not Fixed Follow the hardware configuration WinAC IE 0 0 Or Follow the hardware configuration - Test Connection - Press button to check the connection to the requested PLC using the specified address, slot and rank.

- Sampling interval - The sampling interval (in ms) to use to read data from PLC.

- Use global writing thread - Forces FlexSim to write values to PLC using a single thread that caches writing requests and sends all at once to optimize connection times.

- Writing interval - If Use global writing thread is selected, this is the interval time (in ms) of the writing thread

- Import PLC Tags - Press button to import PCL Tags from a TIA Portal Excel output into a connection table.

- Open Tags table - Press button to open the table containing PCL Tags imported from TIA Portal.

- Synchronize vars - Press button to create/update controls and sensors according with import table.

- Synchronize table - Press button to update import table according with connection controls and sensors.

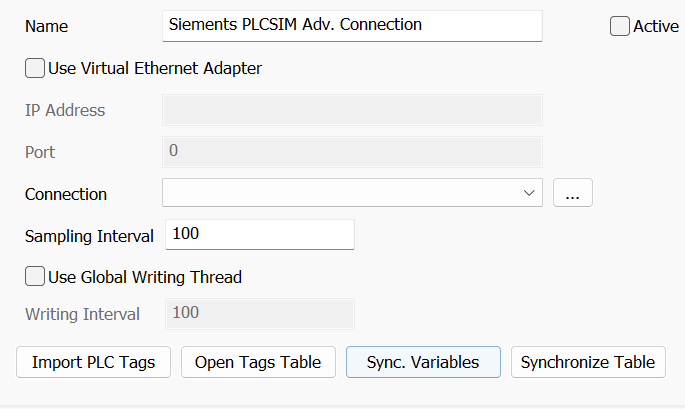

Siemens PLCSIM Advanced

PLCSIM Advanced connections can be related to local or remote sessions of Siemens SIMATIC S7-PLCSIM Advanced v3.0: connections don't depend from underlying simulated PLC.

- Name - The name of the connection. Used for identifying the connection in FlexSim.

- Active - If checked, a connection will be created to connect FlexSim to a PLCSIM Advanced instance. This occurs when the model starts running.

- Use Virtual Ethernet Adapter -

when checked, it makes Flexsim connect to PLCSIM Advanced via TCP/IP.

This way is suitable for both local or remote connections.

If it's not checked Flexsim communicates via Softbus, only suitable for local connections. - IP address / Port - Connection parameters for TCP/IP connections.

- Connection - The connection combo lists the instances found on the PLCSIM Advanced: only a running instance can be used during simulation. Press the button close to this control to test the connection and to update the instances list

- Sampling interval - The sampling interval (in ms) to use to read data from PLC.

- Use global writing thread - Forces Flexsim to write values to PLC using a single thread that caches writing requests and sends all at once to optimize connection times.

- Writing interval - If Use global writing thread is selected, this is the interval time (in ms) of the writing thread

- Import PLC Tags - Press button to import PCL Tags from the selected instance.

- Open Tags table - Press button to open the table containing PCL Tags imported from TIA Portal.

- Synchronize vars - Press button to create/update controls and sensors according with import table.

- Synchronize table - Press button to update import table according with connection controls and sensors.

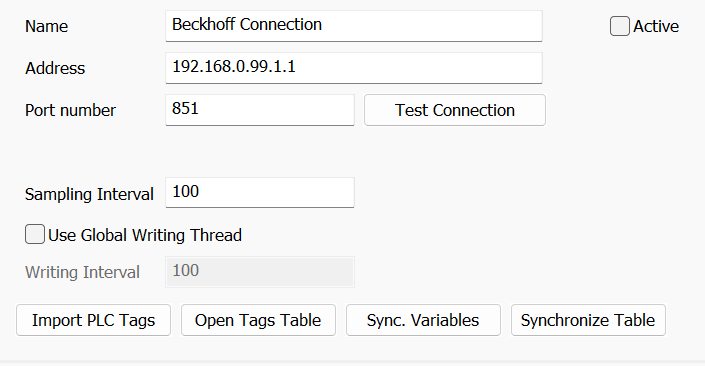

Beckhoff

Beckhoff connections don't depend from underlying simulated PLC.

- Name - The name of the connection. Used for identifying the connection in FlexSim.

- Active - If checked, a connection will be created to connect FlexSim to a PLCSIM Advanced instance. This occurs when the model starts running.

- Address - the AMS NetID of the system to connect to.

- Port number - Connection parameters for TCP/IP connections.

- Test Connection - Press button to check the connection to the requested system using the specified address and port number.

- Sampling interval - The sampling interval (in ms) to use to read data from PLC.

- Use global writing thread - Forces Flexsim to write values to PLC using a single thread that caches writing requests and sends all at once to optimize connection times.

- Writing interval - If Use global writing thread is selected, this is the interval time (in ms) of the writing thread

- Import PLC Tags - Press button to import PCL Tags from the selected instance.

- Open Tags table - Press button to open the table containing PCL Tags imported from TIA Portal.

- Synchronize vars - Press button to create/update controls and sensors according with import table.

- Synchronize table - Press button to update import table according with connection controls and sensors.

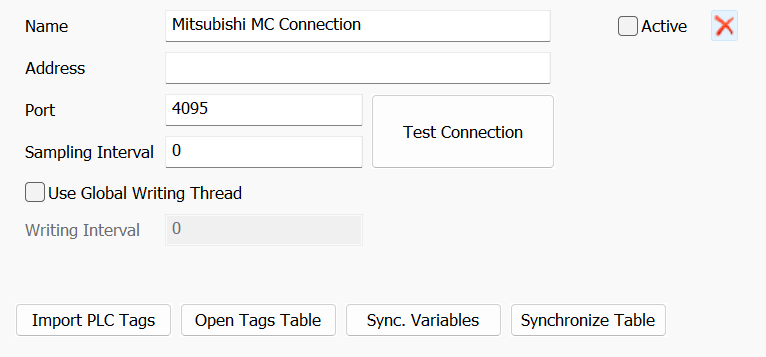

Mitsubishi

Mitsubishi connection lets FlexSim communicate with physical MELSEC

iQ-R or Q/L series PLCs.

- Name - The name of the connection. Used for identifying the connection in FlexSim.

- Active - If checked, a connection will be created to connect FlexSim to a PLCSIM Advanced instance. This occurs when the model starts running.

- Address - The IP address of the PLC.

- Port number - TCP port, usually 4095.

- Test Connection - Press button to check the connection to the requested system using the specified address and port number.

- Use global writing thread - Forces Flexsim to write values to PLC using a single thread that caches writing requests and sends all at once to optimize connection times.

- Writing interval - If Use global writing thread is selected, this is the interval time (in ms) of the writing thread

- Import PLC Tags - Press button to import PCL Tags from the selected instance.

- Open Tags table - Press button to open the table containing PCL Tags imported from TIA Portal.

- Synchronize vars - Press button to create/update controls and sensors according with import table.

- Synchronize table - Press button to update import table according with connection controls and sensors.

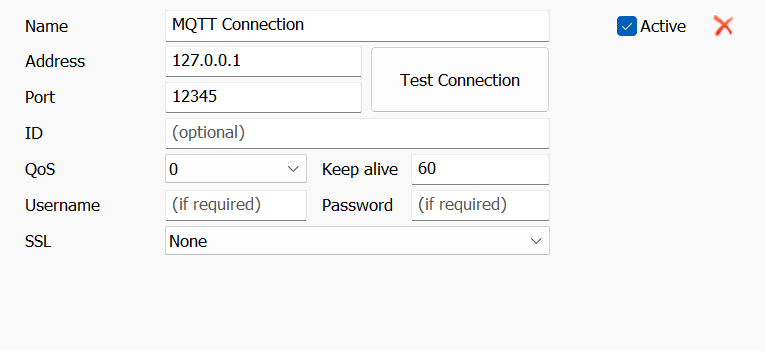

MQTT

MQTT connection lets FlexSim to communicate with MQTT brokers as publisher/subscriver client.

- Name - The name of the connection. Used for identifying the connection in FlexSim.

- Active - If checked, a connection will be created to connect FlexSim to a PLCSIM Advanced instance. This occurs when the model starts running.

- Address - The IP address of the MQTT broker.

- Port number - The TCP port. The default unencrypted MQTT port is 1883. The encrypted port is 8883.

- Test Connection - Press button to check the connection to the requested system using the specified address and port number.

- ID - The ID of the client. If left blank, a random ID will be used.

- QoS - Quality of Service.

Available values are 0,1,2:

QoS Publisher Subscriber 0: at most once Will send a message only once. Might receive or might not receive the message. 1: at least once Will send a message at leastonce as long as an acknowledgement is received or the command to end the transmission is received. It is likely to receive the message at least once (it is possible that the message can be received more than once). 2: exactly once Will only send a message once. Will only receive the message once. - Username - The username for this connection. Only required if the broker requires a username/password.

- Password - The password for this connection. Only required if the broker requires a username/password.

- SSL - Specify the SSL options for

this connection:

Method Description None This connection won't use SSL. PSK Use pre-Shared Key (PSK) authentication method.

This method requires you to provide a PSK key and a identity string.

See below for detail.CA/Cert Use Transport Layer Security (TLS) and Secure Sockets Layer (SSL) provide a secure communication channel.

This method requires to provide:

- PEM encoded trusted CA certificate file.

- PEM encoded certificate file for this client.

- PEM encoded private key for this client.

- If the key file is encrypted, the passphrase for the key.

- PSK Identity - The identity of this client. May be used as the username depending on the server settings.

- PSK - The pre-shared-key string in hex format with no leading “0x”.

- CA File - Path to a file containing the PEM encoded trusted CA certificate file.

- Certificate - Path to a file containing the PEM encoded certificate file for this client. Can be left empty: in this case no client certificate will be used.

- Private Key - path to a file containing the PEM encoded private key for this client. This parameter is not required when the 'Certificate' field is empty.

- Passkey - The decryption key for the Private Key. Only required if the Private Key is encrypted.

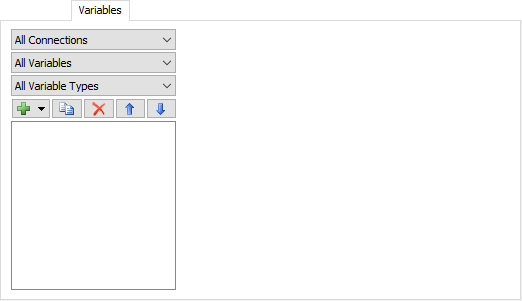

The Variables Tab

The Variables tab has the following properties:

Filters

There are three ways of filtering the Variables List:

- Connections - Only display connections of this type.

- Variables - This can be either local variables, which are variables created using the Emulation tool window, or it can display process flow variables that are dynamically created.

- Variable Types - Only display variables of this type.

| Icon | Description |

|---|---|

|

Adds a variable. |

|

Duplicates the selected variable. |

|

Removes the selected variable. |

|

Moves the selected variable up in the list. |

|

Moves the selected variable down in the list. |

Variables List

Displays a list of variables.

There are three types of variables that can be added, Sensors (PLC Inputs), Controls (PLC Outputs) and Data.

Sensors (PLC Inputs)

Sensors are used to write data to the PLC, server or data variable. If you read from a sensor, the value returned will be the local value stored in FlexSim. If the sensor's connection is active, then changing its value will cause that value to be written to the PLC or server. If the connection is inactive, the value will only be changed locally.

Controls (PLC Outputs)

Controls are used to read data from the PLC, server or data variable. A control can only be changed if the control's connection is inactive. This allows your internal ladder logic to act as the PLC and make changes to controls which can start/stop motors, etc. If you attempt to change a control's value when its connection is active, an exception will be thrown.

When you read from a control, the returned value depends on how the control is setup. If the control is set to Subscribe to Changes or Poll for External Changes (depending on the connection type), the server will notify FlexSim of the changed value (subscribing) or FlexSim will ask for changes using events (polling). If you later try and read the value from these controls, the returned value will be the cached value from the last time FlexSim read the value. If Subscribe to Changes or Poll for External Changes is not checked, reading a control's value will reach out to the PLC or server and read the value synchronously (FlexSim will wait until it receives the value back before the simulation will continue) or asynchronously.

Data

Some connection types, like the Allen-Bradley Connection, have an additional data variable type that pulls data from the server/PLC and then links to sensor and control type variables. These variables are not associated with an object in the model.

The properties of these variables are described below.

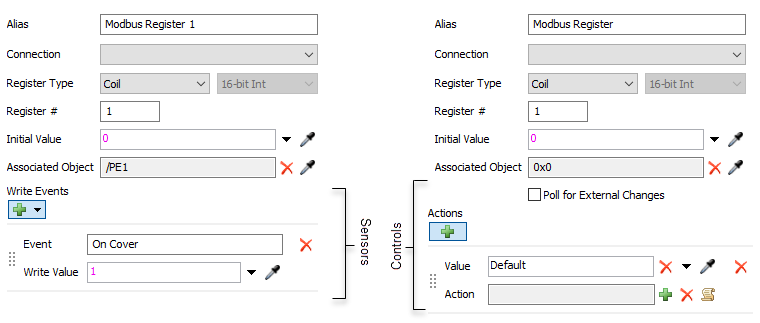

Modbus Register

Properties for Modbus Register variables are very similar between the Sensor and Control. These properties are described below.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Connection - The connection this variable is associated with.

- Register Type - The type of register. This can be Coil, Discrete Input, Holding Register, Input Register. For holding and Input register, the data type drop down button defines what data type the register is.

- Register # - Define the register's address (0 - 9999).

- Initial Value - The initial value of the register. This is only available for Server or Slave type connections that store their own data.

- Associated Object - Links this

variable with an object in the model. The associated object defines

which Write Events are available

for sensors. In the pick options for Write Events

and Actions,

currentis the associated object. - Write Events - If the sensor has

an associated object, events on that object can be listened to. Click

on the

to add a new

event.

to add a new

event. - Event - The event to listen to.

- Write Value - The value to write to the sensor (and server if the connection is active).

- Poll for External Changes - Polls the slave or server for changes to the control's value. This is only available for master and client type connections.

- Actions - When polling for

changes, a FlexSim event will be created based upon the connection's

Change Interval. When the event fires

it will read values from the server. If the control's value has

changed, the control's actions will be evaluated. Each action is

evaluated from the top down until the new value matches the Value field or it hits a Default.

The Action will then be fired and no

further actions will be tested. Click on the

to add a new action.

to add a new action. - Value - The value to match.

- Action - Actions to take when the new value matches the Value.

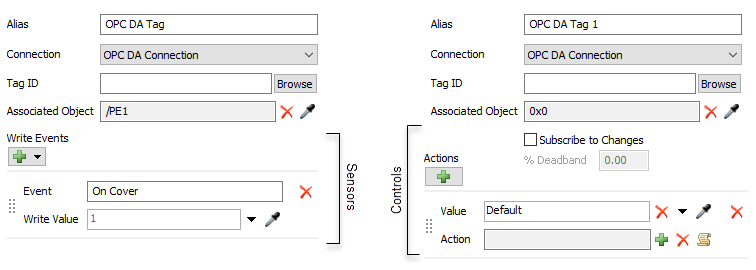

OPC DA Tag

Properties for OPC Tag variables are very similar between the Sensor and Control. These properties are described below.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Connection - The connection this variable is associated with.

- Tag ID - The path of the tag on the server. Click on the Browse button to display a list of the server's available tags.

- Associated Object - Links this

variable with an object in the model. The associated object defines

which Write Events are available

for sensors. In the pick options for Write Events

and Actions,

currentis the associated object. - Write Events - If the sensor has

an associated object, events on that object can be listened to. Click

on the

to add a new

event.

to add a new

event. - Event - The event to listen to.

- Write Value - The value to write to the sensor (and server if the connection is active).

- Subscribe to Changes - Subscribes to changes on the server. FlexSim will be notified when the value changes.

- % Deadband - When subscribing to analog changes, the % deadband can filter out small changes to the control's value (noise).

- Actions - When subscribing to

changes, a change notification will be sent to FlexSim when the

control's value changes. Actions allow you to define what happens

with that notification based upon the new value. Each action is

evaluated from the top down until the new value matches the Value field or it hits a Default.

The Action will then be fired and no

further actions will be tested. Click on the

to add a new action.

to add a new action. - Value - The value to match.

- Action - Actions to take when the new value matches the Value.

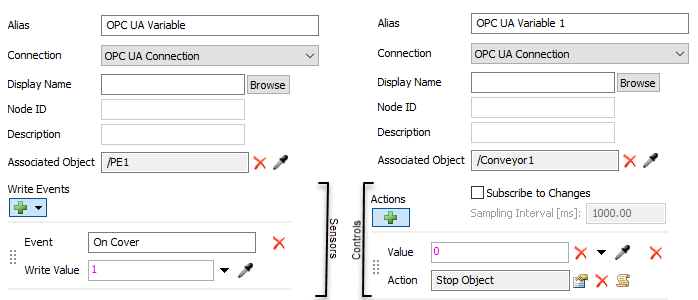

OPC UA Variable

Properties for OPC UA Variables are very similar between the Sensor and Control. These properties are described below.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Connection - The connection this variable is associated with.

- Display Name - The path of the variable on the server. Click on the Browse button to display and select from a list of the server's available tags.

- Node ID - Displays the UA id string of the variable.

- Description - Displays the UA description of the variable.

- Associated Object - Links this

variable with an object in the model. The associated object defines

which Write Events are available

for sensors. In the pick options for Write Events

and Actions,

currentis the associated object. - Write Events - If the sensor has

an associated object, events on that object can be listened to. Click

on the

to add a new

event.

to add a new

event. - Event - The event to listen to.

- Write Value - The value to write to the sensor (and server if the connection is active).

- Subscribe to Changes - Subscribes to changes on the server. FlexSim will be notified when the value changes.

- Sampling Interval [ms] - Defines how often the variable will be sampled from the serve to detect changes to the variable.

- Actions - When subscribing to

changes, a change notification will be sent to FlexSim when the

control's value changes. Actions allow you to define what happens

with that notification based upon the new value. Each action is

evaluated from the top down until the new value matches the Value field or it hits a Default.

The Action will then be fired and no

further actions will be tested. Click on the

to add a new action.

to add a new action. - Value - The value to match.

- Action - Actions to take when the new value matches the Value.

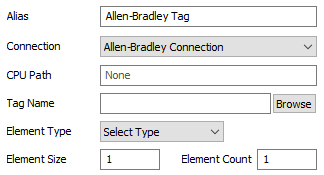

Allen-Bradley Tag

Allen-Bradley tags communicate directly with the PLC to read and write data. Allen-Bradley controls and sensors are then linked to a tag where they will get and set values of the tag. This allows you to pull in large amounts of data from the PLC in a single network request rather than one request per variable. A tag can point to a single element or multiple elements. When linked to multiple elements, FlexSim will treat the tag data as an array.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Connection - The connection this variable is associated with.

- CPU Path - For PLCs that require additional routing, this is the path to the CPU that the tag will communicate with. For example, 1, 0.

- Tag Name - The name of the tag on the PLC. This must be the full name of the tag. If accessing a single element from an array, specify the element using TestBigTag[10,42]. Click on the Browse button to display a list of the PLC's available tags.

- Element Type - Defines the data type of each element in the tag.

- Element Size - The data size of each element in bytes.

- Element Count - The number of elements for the tag.

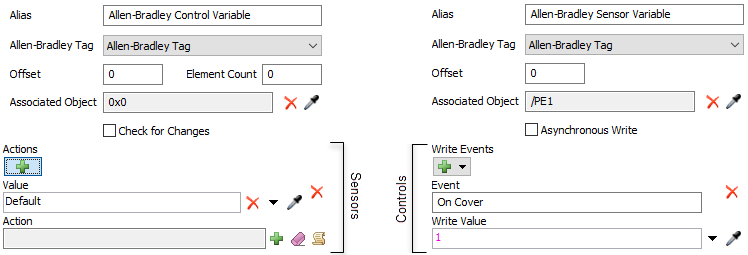

Allen-Bradley Variable

Properties for Allen-Bradley Variables are very similar between the Sensor and Control. These properties are described below.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Allen-Bradley Tag - The Allen-Bradley tag this variable is associated with.

- Offset - The first element (0 based) in the Allen-Bradley Tag to start reading from. For example, if the tag's value is [3, 5, 6, 9] and offset is set to 2, the control value will start at 6.

- Element Count - For controls only. This is the number of elements to read from the Allen-Bradley Tag from the Offset. For element counts great than 1, the value will be an array.

- Associated Object - Links this

variable with an object in the model. The associated object defines

which Write Events are available

for sensors. In the pick options for Write Events

and Actions,

currentis the associated object. - Asynchronous Write - For sensors only. this option is only available if the connection is not set to use Asynchronous Write. If unchecked, FlexSim will wait until the write operation is complete before continuing execution. Otherwise FlexSim will continue running and not wait for the write operation to finish.

- Write Events - If the sensor has

an associated object, events on that object can be listened to. Click

on the

to add a new

event.

to add a new

event. - Event - The event to listen to.

- Write Value - The value to write to the sensor (and PLC if the connection is active).

- Check for Changes - If checked, the linked Allen-Bradley Tag will be set to poll the PLC for changes to the tag. If the control variable's data has been changed, the tag will cause the variable's value to be updated.

- Actions - When checking for

changes, a FlexSim event will be created based upon the connection's

Change Interval. When the event fires

it will read values from the PLC. If the control's value has

changed, the control's actions will be evaluated. Each action is

evaluated from the top down until the new value matches the Value field or it hits a Default.

The Action will then be fired and no

further actions will be tested. Click on the

to add a new action.

to add a new action. - Value - The value to match.

- Action - Actions to take when the new value matches the Value.

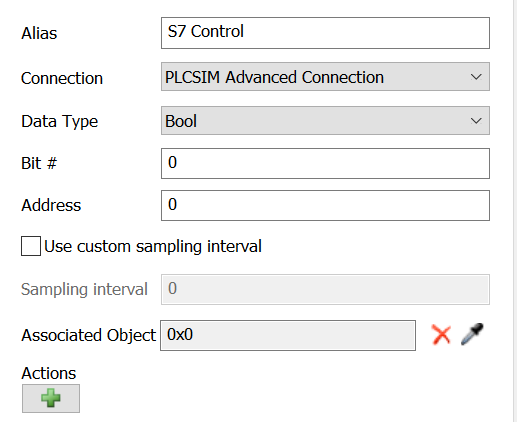

Siemens S7 and Siemens PLCSIM Advanced Control

Properties for both S7 and PLCSIM Advanced controls are described below.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Connection - The connection this variable is associated with.

- Data Type - The Siemens data type the control is associated to: pls note that non all data types are present since not all data types are managed by Flexsim.

- Bit # - Bit number: the bit number in the byte for Boolean data type controls, as reported by TIA Portal.

- Address - The address of the tag as reported by TIA Portal.

- Use custom sampling interval - When checked, it make Flexsim use a custm sampling thread for this control. Otherwise the connection's sampling thread is used.

- Sampling interval - The sampling interval (in ms) to use where a custom sampling thread is used.

- Associated Object - Links this

variable with an object in the model. The associated object defines

the

currentobject in triggers invoked ad sampled value change. - Actions - Press button to select the actions to perform when a sampled value changes.

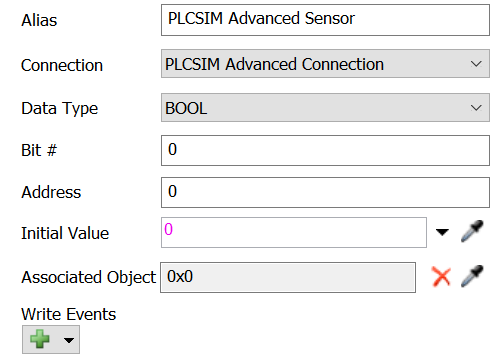

Siemens S7 and Siemens PLCSIM Advanced Sensor

Properties for both S7 and PLCSIM Advanced sensors are described below.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Connection - The connection this variable is associated with.

- Data Type - The Siemens data type the control is associated to: pls note that non all data types are present since not all data types are managed by Flexsim.

- Bit # - Bit number: the bit number in the byte for Boolean data type controls, as reported by TIA Portal.

- Address - The address of the tag as reported by TIA Portal.

- Initial value - The initial value to set in the PLC at reset.

- Associated Object - Links this

variable with an object in the model. The associated object defines

which Write Events are available

for sensors. In the pick options for Write Events

and Actions,

currentis the associated object. - Write Events - If the sensor has

an associated object, events on that object can be listened to. Click

on the

to add a new

event.

to add a new

event. - Event - The event to listen to.

- Write Value - The value to write to the sensor (and server if the connection is active)

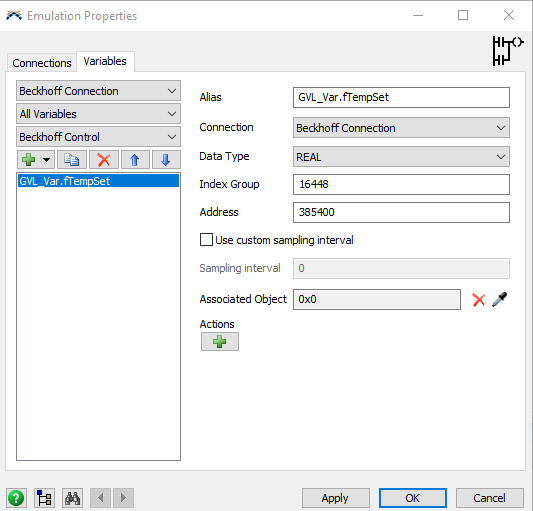

Beckhoff Control

Properties for Beckhoff controls are described below.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Connection - The connection this variable is associated with.

- Data Type - The Beckhoff data type the control is associated to: pls note that non all data types are present since not all data types are managed by Flexsim.

- Index Group - Index group of the variable you want to associate to the control.

- Address - The address of variable you want to associate to the control.

- Use custom sampling interval - When checked, it make Flexsim use a custm sampling thread for this control. Otherwise the connection's sampling thread is used.

- Sampling interval - The sampling interval (in ms) to use where a custom sampling thread is used.

- Associated Object - Links this

variable with an object in the model. The associated object defines

the

currentobject in triggers invoked ad sampled value change. - Actions - Press button to select the actions to perform when a sampled value changes.

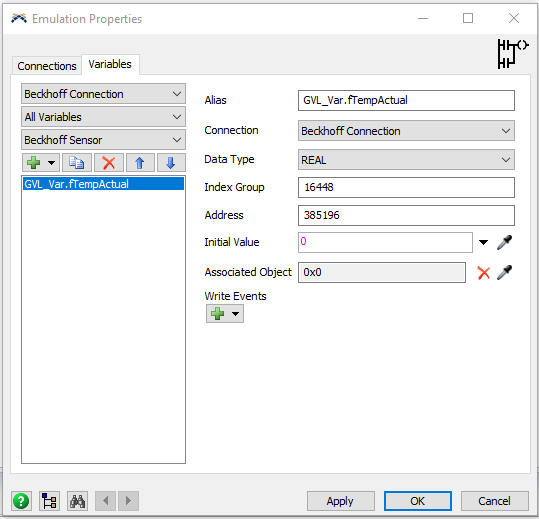

Beckhoff Sensor

Properties for Beckhoff sensors are described below.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Connection - The connection this variable is associated with.

- Data Type - The Beckhoff data type the control is associated to: pls note that non all data types are present since not all data types are managed by Flexsim.

- Index Group - Index group of the variable you want to associate to the control.

- Address - The address of variable you want to associate to the control.

- Initial value - The initial value to set in the PLC at reset.

- Associated Object - Links this

variable with an object in the model. The associated object defines

which Write Events are available

for sensors. In the pick options for Write Events

and Actions,

currentis the associated object. - Write Events - If the sensor has

an associated object, events on that object can be listened to. Click

on the

to add a new

event.

to add a new

event. - Event - The event to listen to.

- Write Value - The value to write to the sensor (and server if the connection is active).

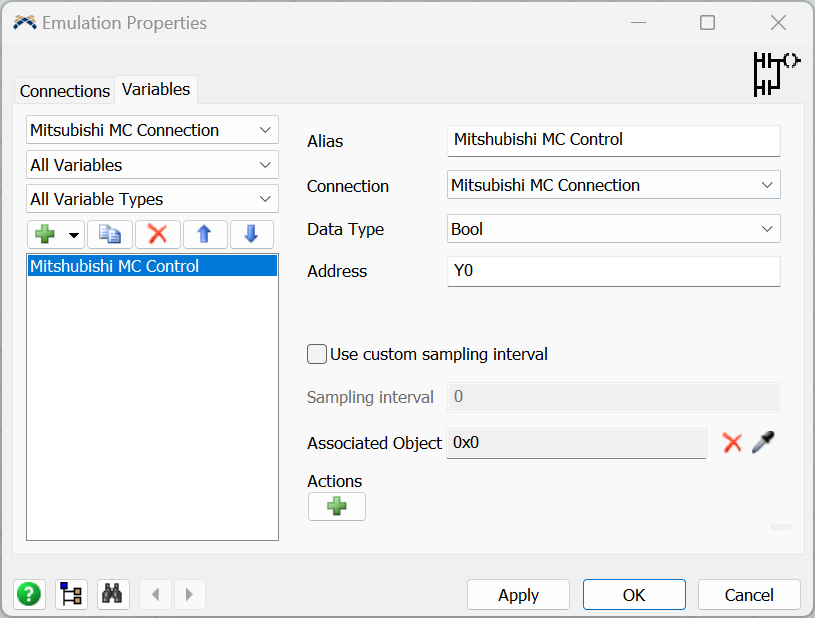

Mitsubishi Control

Properties for Mitsubishi controls are described below.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Connection - The connection this variable is associated with.

- Data Type - The MC data type the control is associated to: pls note that non all data types are present since not all data types are managed by Flexsim.

- Address - The address of variable

you want to associate to the control. In a MELSEC system the address

is string composed by a device name followed by a device

number(an offset). FlexSim currently support following device

names:

Device Name Symbol Type Special Relay SM Bit Special Register SD Word Input X Bit Output Y Bit Latch Relay L Bit Internal Relay M Bit Data Register D Word - Use custom sampling interval - When checked, it make Flexsim use a custom sampling thread for this control. Otherwise the connection's sampling thread is used.

- Sampling interval - The sampling interval (in ms) to use where a custom sampling thread is used.

- Associated Object - Links this

variable with an object in the model. The associated object defines

the

currentobject in triggers invoked ad sampled value change. - Actions - Press button to select the actions to perform when a sampled value changes.

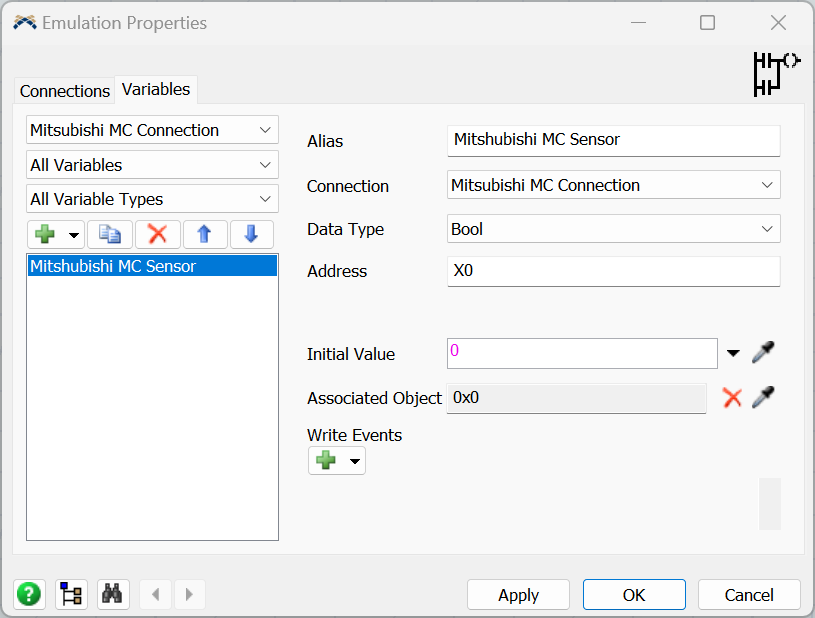

Mitsubishi Sensor

Properties for Mitsubishi sensors are described below.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Connection - The connection this variable is associated with.

- Data Type - The Beckhoff data type the control is associated to: pls note that non all data types are present since not all data types are managed by Flexsim.

- Index Group - Index group of the variable you want to associate to the control.

- Address - The address of variable you want to associate to the control.

- Initial value - The initial value to set in the PLC at reset.

- Associated Object - Links this

variable with an object in the model. The associated object defines

which Write Events are available

for sensors. In the pick options for Write Events

and Actions,

currentis the associated object. - Write Events - If the sensor has

an associated object, events on that object can be listened to. Click

on the

to add a new

event.

to add a new

event. - Event - The event to listen to.

- Write Value - The value to write to the sensor (and server if the connection is active).

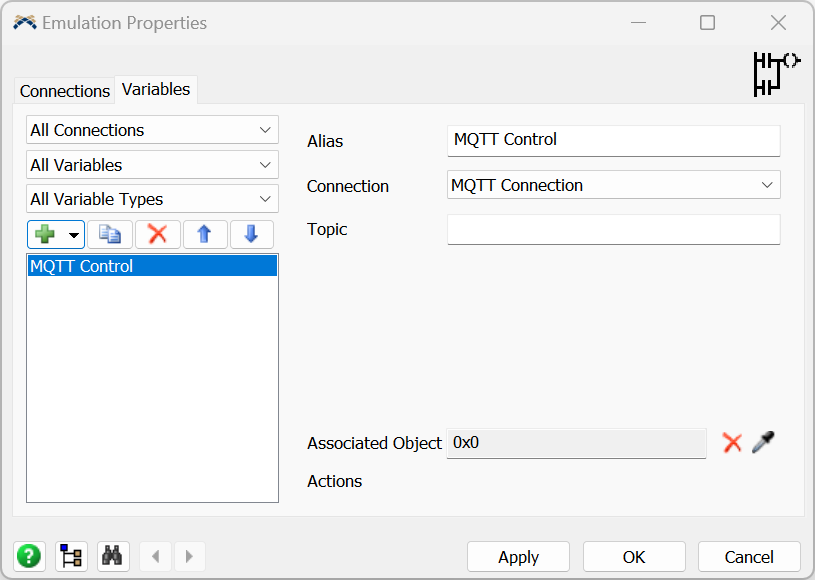

MQTT Control (subscriber)

Properties for Mitsubishi controls are described below.

The MQTT Control is as a MQTT subscriber.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Connection - The connection this variable is associated with.

- Topic - And UTF-8 string that define the topic to subscribe.

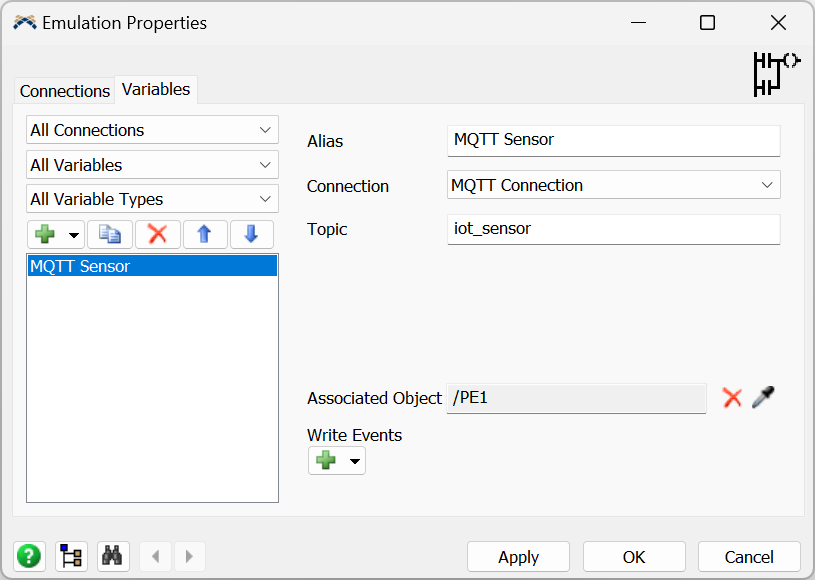

MQTT Sensor (publisher)

Properties for MQTT Sensors are described below.

The MQTT Sensor is as a MQTT publisher.

- Alias - The name of the variable. Used for identifying the variable in FlexSim.

- Connection - The connection this variable is associated with.

- Topic - And UTF-8 string that define the topic to publish.